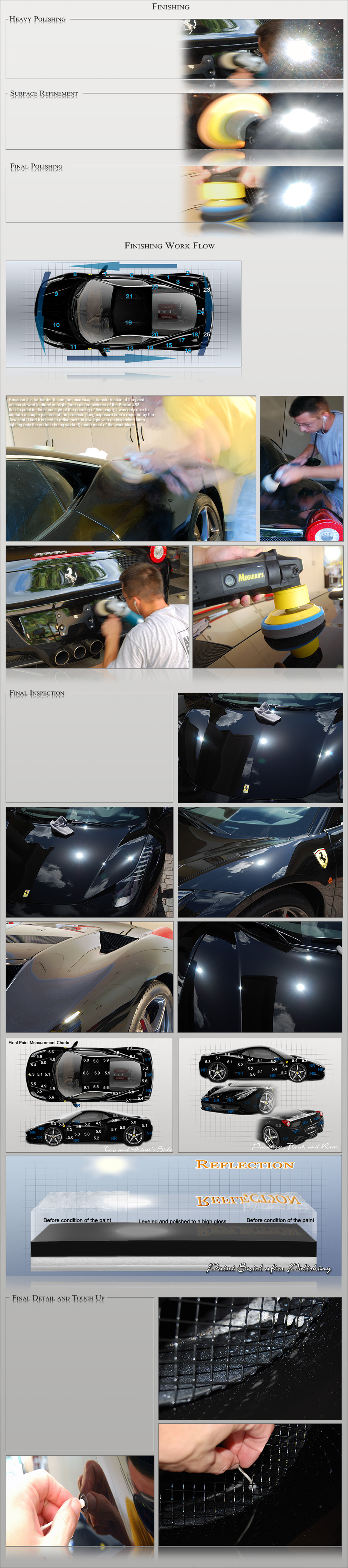

With Ferrari’s texture now level, work began on refining the surface to the

finest degree. The first step in creating a flawless finish was the elimination

of extremely fine surface marring caused by the sanding and cutting process.

Defects were removed using a rotary polisher and a foam compounding pad.

Although the extremely hard clear coat resisted change valiantly, patience,

proper technique, and a keen eye guaranteed results. Average paint thickness

removed during this step: less then .1 mil. Total average paint removed to this

point: .33 mils.

finest degree. The first step in creating a flawless finish was the elimination

of extremely fine surface marring caused by the sanding and cutting process.

Defects were removed using a rotary polisher and a foam compounding pad.

Although the extremely hard clear coat resisted change valiantly, patience,

proper technique, and a keen eye guaranteed results. Average paint thickness

removed during this step: less then .1 mil. Total average paint removed to this

point: .33 mils.

A moderately abrasive polish was used to eliminate remaining imperfections

caused by the heavy polishing. The black paint was nearly flawless at this

point, even after being stripped of all oils and residue with alcohol. If viewed

in direct sunlight from less than a foot away, some minute marring was

evident. Except for the rear vent and driver’s side roof, all surface refinement

(medium grade polishing) was finished by the end of day four. Average paint

thickness removed during this step less then .1 mil. Total average paint

removed to this point: .35 mils

caused by the heavy polishing. The black paint was nearly flawless at this

point, even after being stripped of all oils and residue with alcohol. If viewed

in direct sunlight from less than a foot away, some minute marring was

evident. Except for the rear vent and driver’s side roof, all surface refinement

(medium grade polishing) was finished by the end of day four. Average paint

thickness removed during this step less then .1 mil. Total average paint

removed to this point: .35 mils

The goal: to create a highly jeweled paint surface by artfully and gently

burnishing the Ferrari’s clear coat to a level that would rival a perfectly graded

diamond. The polish I used for this task was a finer version of the type and

brand used by the Ferrari Factory. The application was surgically precise.

Results were scrutinized until they were true and accurate and the reflection

blinding. Average paint thickness removed during this step: Not measurable.

Total average paint removed during the total paint correction process:.35 mils.

burnishing the Ferrari’s clear coat to a level that would rival a perfectly graded

diamond. The polish I used for this task was a finer version of the type and

brand used by the Ferrari Factory. The application was surgically precise.

Results were scrutinized until they were true and accurate and the reflection

blinding. Average paint thickness removed during this step: Not measurable.

Total average paint removed during the total paint correction process:.35 mils.

Each finishing step was performed in the

same direction as the previous cutting steps.

When cutting the paint, each section was

worked independently and all processes were

completed prior to moving on to the next

section. However, with the finishing steps, from

heavy polishing to the final burnishing, each

step was carried over the entire car. After each

process the Ferrari was carefully washed and

dried to prevent any unwanted residual dust

grains from causing microscopic marring as

the surface was polished.

By keeping the work flow consistent the risk of

over polishing was kept to minimum. This way

only the absolute minimal amount of clear coat

was removed through out the process.

same direction as the previous cutting steps.

When cutting the paint, each section was

worked independently and all processes were

completed prior to moving on to the next

section. However, with the finishing steps, from

heavy polishing to the final burnishing, each

step was carried over the entire car. After each

process the Ferrari was carefully washed and

dried to prevent any unwanted residual dust

grains from causing microscopic marring as

the surface was polished.

By keeping the work flow consistent the risk of

over polishing was kept to minimum. This way

only the absolute minimal amount of clear coat

was removed through out the process.

After receiving corrective surgery for the remainder of the previous five days,

the 458’s paint was flawless but it’s body was soiled. Still covered in ultra

fine dust from the last polishing step, the paint was inspected in direct

sunlight. I was looking for any flaws that scarred the otherwise perfectly

jeweled surface. The

Ferrari was left in the sun until the surface was hot to the touch to ensure

that no fillers or solvents remained on the paint. After a thorough inspection,

the Ferrari was pulled back into the garage. As the paint cooled, the surface

was inspected using a portable UV light, looking for any discrepancies in

the paint texture. One spot, about three inches long on the upper driver’s

side rear fender needed slight refining. It was only after passing the final,

determined inspection that the 458 was cleared and I was satisfied with

the finish.

The paint was then re-measured for thickness and all numbers were

charted.The total average of paint film removed was 35/1000ths of an inch

or .35 mils (roughly 9 microns), with a high of .6 mils (15 microns) and a

low of .2 mils (5 microns).

the 458’s paint was flawless but it’s body was soiled. Still covered in ultra

fine dust from the last polishing step, the paint was inspected in direct

sunlight. I was looking for any flaws that scarred the otherwise perfectly

jeweled surface. The

Ferrari was left in the sun until the surface was hot to the touch to ensure

that no fillers or solvents remained on the paint. After a thorough inspection,

the Ferrari was pulled back into the garage. As the paint cooled, the surface

was inspected using a portable UV light, looking for any discrepancies in

the paint texture. One spot, about three inches long on the upper driver’s

side rear fender needed slight refining. It was only after passing the final,

determined inspection that the 458 was cleared and I was satisfied with

the finish.

The paint was then re-measured for thickness and all numbers were

charted.The total average of paint film removed was 35/1000ths of an inch

or .35 mils (roughly 9 microns), with a high of .6 mils (15 microns) and a

low of .2 mils (5 microns).

All the painted surfaces of the Ferrari, including the door jambs,

wheel arch lips, bonnet, and engine lid rails were carefully washed

and pressure cleaned to remove any dust. A degreaser solution and

cotton swabs were used to clean inside of vents, around emblems,

and parking sensors.

The Ferrari was then rinsed with de-ionized water and blown dry

with heated air. Any remaining water was lightly wiped away with a

very soft microfiber towel.

All of the exterior trim was treated with a UV inhibiting protectant. The

tires, deep cleaned initially, were dried and treated with two coats of

a water based dressing, safe for use around the carbon ceramic

brake rotors.

The wheels and brake calipers were treated with a heat resistant

sealant.

The glistening paint was treated with a pre cleaner then coated with

two coats of a high solid polymer sealant, allowed to cure in

between coats. Lastly, a select carnauba wax was applied atop the

sealed paint, giving the sharp reflections the illusion of depth and

fourth adding valuable protection against the environment.

The absolute last step was pulling the newly perfected Ferrari 458

Italia outside and trying my best to capture her beauty

wheel arch lips, bonnet, and engine lid rails were carefully washed

and pressure cleaned to remove any dust. A degreaser solution and

cotton swabs were used to clean inside of vents, around emblems,

and parking sensors.

The Ferrari was then rinsed with de-ionized water and blown dry

with heated air. Any remaining water was lightly wiped away with a

very soft microfiber towel.

All of the exterior trim was treated with a UV inhibiting protectant. The

tires, deep cleaned initially, were dried and treated with two coats of

a water based dressing, safe for use around the carbon ceramic

brake rotors.

The wheels and brake calipers were treated with a heat resistant

sealant.

The glistening paint was treated with a pre cleaner then coated with

two coats of a high solid polymer sealant, allowed to cure in

between coats. Lastly, a select carnauba wax was applied atop the

sealed paint, giving the sharp reflections the illusion of depth and

fourth adding valuable protection against the environment.

The absolute last step was pulling the newly perfected Ferrari 458

Italia outside and trying my best to capture her beauty

Page 6) Finishing

PREVIOUSLY FEATURED DETAIL:

ORIGINAL PAINT 427 SHELBY COBRA

ORIGINAL PAINT 427 SHELBY COBRA

Copyright 2010 Bella Detailing, LLC - Todd@belladetailing.com - 407.963.1444

ALL Photographs on this site are property of Todd Helme's Bella Macchina. We do NOT use stock photography and are very proud of the

automobiles we are trusted to care for and shine we create. Please do not use our property with out expressed permission- Todd Helme

automobiles we are trusted to care for and shine we create. Please do not use our property with out expressed permission- Todd Helme